Product Overview

Specifications

Timber Jack 4x4 (TJ-4)

- Load Capacity: 15,000 Lbs / 7.5 Tons

- Overall Height: 9-1/8"

- Base Plate 5"

- Top Plate: 5-1/2"

- Acme Screw Size: 1-1/4"

- Range of Adjustment: 5"

- Lifting Capacity: 4000 Lbs. / 2 Tons

TIMBER JACK 6X6 (TJ-6)

- Load Capacity: 30,000 Lbs / 15 Tons

- Overall Height: 10"

- Base Plate 5"

- Top Plate: 5-1/2"

- Acme Screw Size: 1-1/2"

- Range of Adjustment: 5"

- Lifting Capacity: 4000 Lbs. / 2 Tons

Safe Working Loads

(based on use of southern yellow pine #1)

| Total Shore Height (ft) | Maximum load Capacity (2.5/1 safety factor, lbs.) | |

| TJ-4 | TJ-6 | |

| 4' | 15,000 | 30,000 |

| 6' | 12,000 | 30,000 |

| 8' | 7,200 | 30,000 |

| 10' | 5,000 | 27,000 |

| 12' | 3,000 | 20,000 |

| 14' | 2,600 | 15,000 |

| 16' | 0 | 11,500 |

| 18' | 0 | 8,800 |

| 20' | 0 | 6,000 |

Load capacity based on actual load test results Douglas Fur #1 4x4/6x6 dressed lumber (3.5"/5.5" square). Capacities include a standard 2.5/1 safety factor. Lumber must be cut square on both ends. Do not exceed recommended allowable safe load ratings in the above chart. Do not extend screw past advertised adjustment range. Timber Jacks should be attached to a flat solid foundation and should not be subject to any lateral force. Timber Jacks should be used to support straight vertical loads only. Before construction begins consult with certified engineer for approval of our products within your application.

How To Assemble:

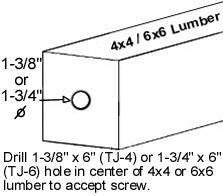

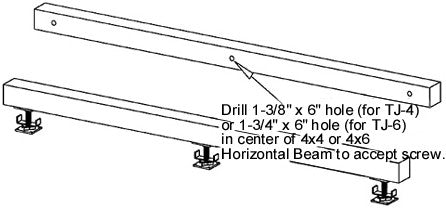

- Drill 1-3/8" x 6" (for TJ-4) or 1-3/4" x 6" (for TJ-6) hole using auger or self feed drill bit into center of lumber to accept 1-1/4" or 1-1/2" Acme threaded screw.

- Position Timber Jack so the Acme screw will slide into the predrilled hole in lumber.

- Adjust the top plate so all 4 mounting holes line up within the boundaries of the lumber.

- Drill 4 - 5/32"x1" holes through the mounting holes in the top plate and into the lumber.

- Insert 4 - 1/4"x1-1/2" lag screws through the mounting holes in the top plate into the predrilled holes in the lumber and tighten.

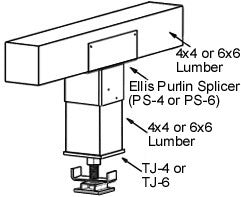

- Attach Ellis Purlin Splicer to Beam or Joist where support is desired.

- Slip 4x4 or 6x6 lumber attached to the Timber Jack into the square tubing of the purlin splicer and secure with nails through the holes provided.

- Adjustment to Timber Jack can be made by turning "U" shaped handle at bottom of screw. Acme threads are greased for easy adjustment.

- Attach base plate to a solid foundation through the 4 holes provided.