Product Overview

The Ellis Mini Jacks are offered in two sizes, with minimum heights of either 6.5" (MJ-3) or 9.5" (MJ-6) and 15,000 lbs. of safe load capacity. Looking for a shorter option? Check out the STEALTH-3, STEALTH-4, and STEALTH-5 Steel Shores.

Demonstration Video

Specifications

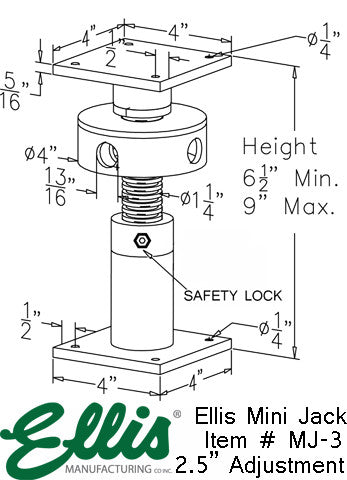

| Ellis Mini Jack 2.5" Adj. (MJ-3) | |

| Load Capacity: | 15,000 Lbs / 7.5 Tons (Includes 2.5 to 1 Factor of Safety) |

| Overall Height Screwed Down: | 6-1/2" |

| Overall Height Fully Extended: | 9" |

| Base Plate: | 4" Sq. |

| Top Plate: | 4" Sq. (Swivels Independently from Screw) |

| Acme Screw Size: | 1-1/4" |

| Range of Adjustment: | 2.5" |

| Lifting Capacity: | 3,000 LBS. w/ 12" turning bar (MJ-TB12). |

| Safety Lock Set Screw: | Included |

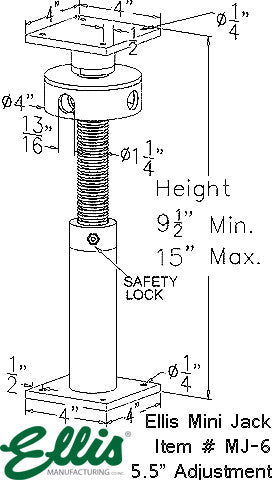

| Ellis Mini Jack 5.5" Adj. (MJ-6) | |

| Load Capacity: | 15,000 Lbs / 7.5 Tons (Includes 2.5 to 1 Factor of Safety) |

| Overall Height Screwed Down: |

9-1/2" |

| Overall Height Fully Extended: |

15" |

| Base Plate: | 4" Sq. |

| Top Plate: | 4" Sq. (Swivels Independently from Screw) |

| Acme Screw Size: | 1-1/4" |

| Range of Adjustment: | 5.5" |

| Lifting Capacity: | 3,000 LBS. w/ 12" turning bar (MJ-TB12). |

| Safety Lock Set Screw: | Included |

*Make adjustments to the height of the Mini Jack by turning the turning wheel. A 3/4" round rod can be used for extra leverage (MJ-TB12). Top plate will swivel independently from the screw.

*Mini Jacks should be attached to a flat solid foundation and should not be subject to any lateral force. Mini Jacks should be used to support straight vertical loads only. We recommend tightening set screw in the side of the 4 hole nut with 6mm allen wrench prior to loading (unless lifting). Before construction begins it is recommended that you consult with certified engineer for approval of our products within your application. Do not extend screw past advertised adjustment range. Do not exceed max safe load capacity.

Shop Drawings and CAD Blocks:

| Item Number | Shop Drawing (.PDF) | AutoCAD Block (.DWG) |

| MJ-3 | MJ-3 Shop Drawing | MJ-3 CAD Block coming soon |

| MJ-6 | MJ-6 Shop Drawing | MJ-6 CAD Block |