Product Overview

All Ellis Light Duty Steel Lifting Shores now come with the 4 lug lifting nut. Used the 3/4" Diameter Steel Adjustment Rod to lift loads up to 20,000 lbs.

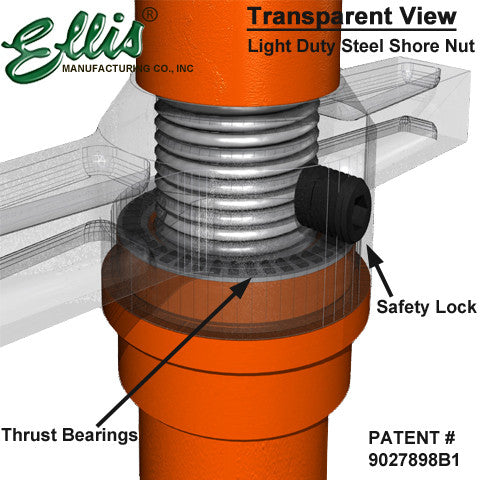

The patented Ellis Thrust Bearings on the Light Duty Lifting Shores enable these shores to lift up to 10x the amount of load compared to the Light Duty Steel Shores (w/o bearings). Adjustable structural support column for temporary or permanent support with a patented nut housing tiny thrust bearings to allow for easier adjustment under load and jacking weight with significantly less force. Add any length 3/4" Diameter Steel Adjustment Rod for extra leverage and lift up to 20,000 lbs.

In the product animation below you will notice the thrust bearings inside the nut. The bearings greatly reduce the amount of friction when the Steel Shore with Roller Bearings - house jack handle is turned to adjust the height under load.

Unlike the Standard Steel Shore, these with Roller Bearings are built as one complete unit to aid in uplift resistance and do not come apart. Furthermore, we've added a "set screw" in the side of the nut, and when tightened down locks the adjustment handle in place for permanent or long term shoring applications.

The 6" x 6" top plate is attached with a clevis pin and interchangeable with different shapes and sizes. Click here to see a few of the different tops to choose from: STEEL SHORE TOPS.

*All Load Capacities include a 2.5 to 1 Factor of Safety.

Demonstration Video

Specifications

Nut Assembly - Forged for durability, galvanized. Houses tiny thrust bearings to allow for much easier adjustment under load. Lockable with safety lock set screw (included) for permanent use.

Top plate - 3/8x6x6" Steel Plate, 4- 3/8" holes (Attaches with clevis pin and Interchangeable with custom U Heads.) See below for more adjustable top plate options.

Base Plate - 3/8"x6" x6", 4- 3/8" Holes (welded to 2" Sched. 40 Pipe). Custom sizes available

Acme Screw - 1-7/8" Dia. (Lengths vary).

Pipe - 2" Sced. 40 (Lengths vary).

Documents:

Shop Drawings:

| Item Number | Shop Drawing (.PDF) | AutoCAD Block (.DWG) |

| STL-8 | STL-8 Shop Drawing | STL-8 CAD Block N/A |

| STL-10 | STL-10 Shop Drawing | STL-10 CAD Block |

| STL-14 | STL-14 Shop Drawing | STL-14 CAD Block |

| STL-22 | STL-22 Shop Drawing | STL-22 CAD Block |

| STL-38 | STL-38 Shop Drawing | STL-38 CAD Block |

| STL-62 | STL-62 Shop Drawing | STL-62 CAD Block |

| STL-86 | STL-86 Shop Drawing | STL-86 CAD Block |

| STL-110 | STL-110 Shop Drawing | STL-110 CAD Block |

Interchangeable Top Plate Options:

- Flat Plate - Standard with any Light Duty Steel Shore

- Lumber U-Head - Compatible with Light Duty Steel Shores and is intended to be used to secure to a horizontal 2x4, 2x6, 4x4, 4x8, 6x6 etc. lumber beam.

- Pivot Flat Plate - This 6" square plate is intended to secure your Light Duty Steel Shore to a beam being supported and will pivot up to 45 degrees. This product fits on Light Duty Steel Shores only.

- Custom Top Plate shapes and sizes specific to Light Duty Steel Shores upon request (800) 654-8311 or store@ellismanufacturing.com.

*Steel Shores should be attached to a flat solid foundation. Steel Shores should not be subject to any lateral force. Steel Shore should be used to support straight vertical loads only. We recommend tightening set screw in the side of the nut with 6mm allen wrench prior to loading. Do not extend screw past advertised adjustment range. Do not exceed max safe load capacity. Before construction begins it is recommended that you consult with a certified engineer for approval of our products within your application.